The

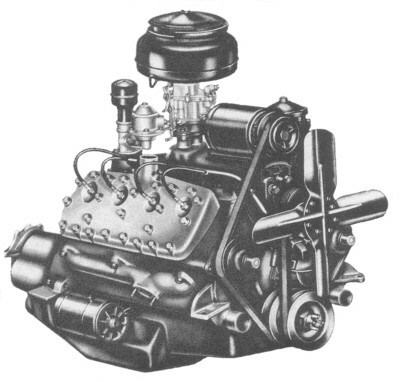

Ford Flathead

Engine

Fabricating the

Parts & Putting It All Together

Making the Headers

Fabricating a

Turbo Header

This article details the process of fabricating a low cost turbo header.

The subject engine is a Toyota 22RE engine using a Garrett T4/T3 hybrid turbo.

Flanges

The head and turbo flanges are laid

out on 3/8 to 1/2 inch mild steel plates using the gaskets as tracing patterns. A drill press and hole saw are used to cut

the holes. For rectangular holes, 4 smaller holes may have to be drilled and then hand filed to obtain the correct shape.

If you have access to a plasma arc cutter, this job will go much faster!

Tubes

This header was constructed from 1 1/4 schedule 40 NSP weld els and tubing. The els are available from most industrial plumbing

and gas fitting shops and are very inexpensive. They are made from a high strength, weldable alloy steel and have a nice V

at each end to pour in a good, strong weld. They are available in 45 and 90 degree bends and short and standard radius styles.

We recommend using the standard, longer radius ones whenever possible as they have less flow restriction. The els are also

available in different IDs. The size describes the approximate ID, not the OD. The 1 1/4 ones are actually about 1 3/8 ID.

Straight schedule 40 NSP tubing is used between els. These parts have a very thick wall thickness so the header will probably

weigh as much as a heavy cast iron manifold. This thickness is necessary with non-stainless tubing

for longevity at the high temperatures encountered. Standard mild steel header tubing will quickly self destruct if used for

a turbo header. These materials have proved to last for several years of hard use on many engines

including road racing applications.

Collector

The collector

is what merges the primary tubes into the turbine inlet. It needs to match the outer circumference of the primary tubes and

the ID at the turbine flange needs to match the hole ID. It is constructed in 4 main parts, made from 1/8 to 3/16 plate stock

which is then welded together. Later, 4 wedges were cut from each corner and 45 degree triangles were added to help match

the tube contours. Alternately, an 8 sided collector can be built or a hammer formed collector made. Hammer forming such thick

plate is very time consuming! For Turbos with round inlet holes, a conical collector needs to be made. This entails cutting

a paper template to simulate the size and shape and lots of cursing and swearing to heat and hammer form into the conical

shape. We recommend that all parts be TIG welded to reduce warp-age. Weld the turbine inlet flange to the collector.

Tube Layout

The turbo should be held in position where it will be mounted. Lots of thought should go into the tube layout to try to maintain

equal lengths if possible and be sure that the tubes clear steering boxes, master cylinders, strut towers etc. It has been

found that actual tube length seems to have little effect on response or power in street applications however, equal lengths

will theoretically give slightly better response. Most of our systems have a 14 to 18 inch primary tube length and this has

worked well.

The 45 and 90 degree els and straight tubing may be duct taped together

to plan the layout. Once you are satisfied with the layout, the tubes may be tacked to the head flange with ONE small tack

on the top. We bolt the flange to a scrap head to aid in tube alignment. Start out from the head flange one piece at a time

working out to-wards the collector.

Once your pipes are all tacked and line up on the collector OK,

carefully bolt the assembly into the car and set the turbo and collector in place. If everything is where you want it, remove

and take it back to the bench. Scribe or mark each tube where it meets the flange and number each tube. Tack each joint in

at least 2 points EXCEPT at the head flange. Now carefully break each tube off of the flange. Weld all the joints completely

on each tube.

Once all the primary tube joints have been welded, they need to

be carefully repositioned as they were before removal from the head flange. Line up your scribe marks and the original tacks.

Tack each tube back in place. The tubes may be moved and twisted slightly to allow the collector ends to meet at the proper

angle and height to align with the collector base. A large hose clamp or vise grips can be used to hold the tubes together.

Once you are satisfied, heavily tack the primaries to the head flange and the ends of the tubes together. Make sure that the

flange is firmly bolted to a scrap head or 1 inch base plate to prevent warp-age. Yes, even 1/2 inch plate will warp.

Center Diamond and Corners

You need to cut and shape corner pieces and a center diamond to plug the holes where the collector meets the primaries. These

should be cut from the 1/8 or 3/16 plate that you used to make the collector. Once satisfied with the fit, weld in place.

You are now ready to weld the collector to the rest of the header.

1/8 X 1 flat stock can be used to brace the edge of the flange to the collector and to the outside of the primaries for extra

strength and longevity.

After ceramic

coating

Coated down pipe and powder coated inter-cooler pipe

T4/T3 hybrid turbo with

H3 compressor, stage 3, .63 exhaust, ceramic coated. A twin port, waste-gate actuator is used for cockpit adjustable boost

via an inexpensive pneumatic regulator.

Complete installation. Note extensive

heat shield to protect master cylinder and brake lines made from aluminum backed Felramic 2000 material.

Section IV

Project:Flathead Starts here!

I hope that helped shed some light on just how Headers are made. The only thing we will

be doing different is the Header Tubing will be much smaller in wall thickness. I have never seen

a Header welded with such thick metal as in the above article. We will be using 1-5/8" mild steel tubing with a

wall thickness of 16 Gauge. The set-up is very similar to the article above, which is why I included it, I was hoping

it would prove useful.

Hopefully you have been following along as we build this

project, if so..you last read how we were building up the Flathead which was just painted back in section III. I cheated

and included a picture from this section to wet your appetite, it was the one where you see one sides finished header and

turbocharger. Believe it or not, I got that side to that state of build, in just a few hours of work (3-4).

On the next side, which will be a mirror image of the first side, I'll go a bit slower and take some pictures as we go.

It was very difficult to take any pictures of the passenger side. I was working alone, and always needed to hold something

or my hands were filthy dirty from the job. Yes ,I wiped all the tubing down with acetone before I started, but

still you get dirty.

The

first picture above is what our J-bend pipes looked like, some times they have a 45° bend in place of the 90° bend.

The second pictures is one of our header flanges. They are water jet cut 3/8" thick steel.

Starting from the begining......I ordered eight (8) 1-5/8" U-Bends and two (2) 1-5/8" J-Bends as a start for the

tubing. We also ordered two (2) 3 into 1 Collectors, and of-coarse all the Turbo-Chargers and their mounting brackets.

The Ford Flathead is unique in that it only has three (3) Exhaust Ports per side, UN-like the usual four (4) Exhaust

Ports on the normal V8 engine. This makes the Headers UN-usual and a little odd looking, but also saves

us fitting and welding on one (1) tube. Before we started any cutting or welding on the Headers, we had to

do alot of thinking and measuring. I tried to conceptualize the Header, with the Turbo-Charger. We needed

to keep the Header up, so it would fit inside the traditional Hot Rod Frame, but not up any more then necessary.

The Header also had to contend with the Turbo-Chargers mounting flange and the SS V-band Clamp, all of

which took up space. Another consideration was the individual Header Tube Length, while I was sure I would

not end up with perfectly equal Tube Lengths, I did want to keep them as close to equal as possible. I don't know

how professional Header builder work, some might use all mathematical formulas, others templates, but I only had

my Imagination. I knew where I wanted the Turbo-Hharger to be, and I knew where I didn't want the tubes

to be, the rest just came as I went along.

This

is a highly polished Stainless Steel exhaust side manifold for the T3-T4 Turbo-charger. These parts look even better

in person, and are what we used on Project:Flathead.

These

are the Exhaust manifold ends for the incoming very hot air of the engine to the Turbo-charger. Again the parts are

highly polished and refined. If compared to the above article, there parts and final header design looks rough to say

the least compared to our parts. Again, if you look around you can fine the nicer stuff, and at very affordable prices.

This

is a 3-into 1 collector, and the same as we used

These

are V-Band Clamps, they are made from Stainless Steel and have highly machined surfaces to seal against.

Before anything got started, I first had to modify all the tubing I had. I started out by cutting all the U-bends in

half, I measured the U-bend section and cut it in half with a band saw. This gave me sixteen (16) short 90° bends

to start work with. To me, the obvious place to start was with one of the out-side Exhaust Ports. I aliened the

Collector with the center of the Engine, and worked by way back from there. Once I had the Collector in place, we could

measure the distance from the first Exhaust Port to the Collector and the distance from the side of the block to the Collector.

With this information, I started cutting some of the short 90° bends to fit. Then just basically re-peated the same

thing for the back Exhaust Port, although there is a slight difference between the two. With these two(2) Ports

fitted, I tach-welded both in place and then had something solid to work off of for the middle Exhaust Port.

This Port was the most challenging, I wanted to keep the tube lengths close, so instead of simply coming out of the engine

and mating up to the Collector with the most direct route, we had to 90° out of the Engine, cross over then under the

first tube and then double 90° back to the Collector. For this section, the J-Bend was just the ticket, I used the

U-Section I saved and three (3) more close 90° short Bends. All in all it turned out pretty good, and I'll promise

to take more pictures when we do the driver side.

These are the latest pictures of the Flathead. The 6" x 6"

timber is being used to hold the engine level (front to back), this way I can get the exhaust flanges installed and tack welded

in place, while it's level. The goal here, is to try and keep the Turbo-Chargers running as level as possible.

Also, note the bottom row and some of the second row, cylinder head studs. With the new Aluminum heads in-place, these

two rows are noticeably short. They will need to be replaced with longer studs. The Nuts should also have

washers underneath them, to prevent damage to the aluminum heads.

10-06-07

I finally got a chance

to do some much needed work on Project:Flathead. Despite the 90°+

Heat, I managed to get several problems crossed off my "To Do" list.

First up was the Drivers side Exhaust Manifold. Too a certain extent, this was really just

a Mirror Image of the passenger side Manifold we made several days ago. So, with that in mind, I measured all

the pieces on the Passenger side and transferred them to tubbing, and then started with the first Exhaust Port from the front,

just like we did on the other side. I didn't automatically cut any of the pieces, instead I used the marks as a

starting point, and checked if that was a valid or invalid mark. The first port was easy and I even took some pictures

that followed along marking our progress.

Once the first port was tack welded in place, we moved to the rear most

port and duplicated what we did on the first port earlier. What you are looking for here, is alignment. We want

the tubes exiting the ports to be square with the block and level with each other.

The last port was much more difficult, just as it had been on the other

side. But, the learning curve had already been sorted-out by the time we got to this side. I really just needed

an extra set of hands, the measurements were pretty easy, just lining everything up to get the proper fit and angle was the

problem. Once I had a good ideal what was needed at the middle port, I could tach weld the close 90° into position

and then it went much easier. This side took about half the time the prior side took, and that's with me having

to remove everything and start over half way through the process. I'm not sure what was different, but I had several

tach welds burn through, and create two large holes, which is my I scraped everything once and started over. One small

hole or two is repairable, but a series of them isn't.

Here the Exhaust Manifold is finished Tack Welded. The V-Band Clamp was slightly different

then the one we used on the opposite side, so I had to insert a thin section of 2-1/2" SS Tubing between the collars

end and the 4-Bolt Flange.

Once the basic Exhaust Manifold was finished, I re-leveled

the engine and made sure the right and left sides were the same. Same distance off the floor and same angle. The

only hitch in the whole thing was the V-Band Clamps I used on this side were different then those on the other side.

They were identical except for the length of the collar where they attach. For some reason, these were shorter, and

when I welded them to the 4-Bolt flange that attachés the Turbo-Charger to the Exhaust Manifold, that difference in

height made the mounting bolts hit. To compensate for this, I had to break those welds, and insert a small portion of

SS-2-1/2" Tubing between the end of the collar and the 4-bolt flange. This allowed the mounting bolts to now work,

without interfering.

At this point the Exhaust Manifolds or Headers were complete,

so we turned our attention elsewhere. Remember when we first installed the new Elderbrock Aluminum Cylinder Heads

? Well, there were several Head Studs

that were to short, and needed to be fixed. This is where we come into play, I had already ordered the new Head Studs

from Mac's, so now was the perfect time to install them. This is one phase of the project I would have rather skipped,

many because I thought it would be a royal pain. This engine had been sitting around with these head studs in-place

for almost 70 years. And the kicker is the one side sat with the head off for at least 40 years. I could only

imagine how this story would go, and how many head studs I would break off tiring to remove them.

I decided to start on the drivers side, this is the side that sat so long with the head removed, so I though I would tackle

the worst side first. I gave every stud a shot of WD40, and began with the first stud using my 1/2" long breaker

bar and a stud remover. The first one took some effort but it broke free, I turned it about half a turn and gave it

another shot of WD40, then removed it form the block. The second one was about the same and so was the third.

In fact, the whole side came off and although tight, they didn't break off in the block like I had imagined they might.

Wow...this was some really good news, and now I think back and I know why the different Head manufacturers don't mention

that you need to remove the head studs of the lower two rows. They fear it would cost them sales because guys like myself

would fear the removal process. I can certainly see their point, but I do think the right thing to do is to list

all the tools and any modifications needed to install their product. Back to the engine....With the one side now complete

of all the removal, I installed the new studs with a dash of Thread-Locker, and checked that the head would still fit.

It did, so we now turned our attention to the other side.

This was the

protected side, so I was thinking it should go as well or better then the first side did. I really couldn't tell

a difference between the two, they both took the same amount of force, which was plenty. I got all the way down to the

last four (4) studs till I ran into trouble. This came completely unexpected, the stud just broke off. No movement

at all, and the worst part about it was when it broke, I was pulling toward me and the wrench hit me dead center in the eye.

Not on the eye, but in it. Lucky for me I had my hand placed just right where there was only about 1" of wrench

handle sticking out past my hand. Besides not being able to focus for 20-30 minuets, I was fine, but will definitely

wear a shiner for some time. The other remaining head studs came out, just as all the rest had, slow and tough.

True fully, I was lucky, I had but one (1) head stud to repair. If you would have asked me how many I would probably

have before I started, It would have been much more then one (1).

Fixing

a head stud is much like fixing any other broken bolt, it just takes time and patience. The good thing about it, was,

it was easy to get at and in plain sight. I center punched the stud which had broken off just below the deck, and drilled

it out with a 5/16" bit. I tried to remove it with a twist out, but that stud wasn't budging. So, I went

ahead and drilled it out to 3/8" which is the same size you would drill anything to tap a 7/16" thread into.

With a little work, and alot more Patience, I had the old stud removed and the threads back in good shape. All that

was left to do was to install all the new studs and tighten them down, just as we did before. With that part done, I

installed the head and hand started all 48 nuts, 24 per side. Then I got all the nuts hand tight, and torqued them down

on both sides. There are several sites that show head torque values and patterns. Basically you start in the middle

and work your way out from both directions, torquing the nuts to a pre-determined value. I like to take the heads studs

down in three separate torquings, working my way up to the final torque.

This is the passenger side of the engine. If you look close enough, you can see all the new

head studs, they are the ones with the black tops, this side had ten (10) new studs installed. The other side had thirteen

(13) installed.

This shot shows the new head studs and the new nut covers installed. I took this picture, because

it's had to see after the Turbo-Charger is re-installed. Those chrome acorn nut covers sure do shine, and give the

engine a whole new look.

With the Head Studs out of the way, I buttoned-up the Cylinder

Heads and installed all the new chrome nut covers. It's really nice to see all the nuts on, and the covers attached.

Just remember that with these aluminum heads, washers under the nuts are a must have item. The washers help even out

the pressure, and keep the nuts from digging into the softer aluminum heads when tightening. If this would have been

an actual running engine, I would have replaced all the head studs with new, ARP high strength head studs. As it is,

I only used new OEM type studs. Of-coarse, the reason for using the high strength ones is to combat the internal pressures

associated with using Turbo-Chargers or anything that would make Boost. The More Air/Fuel we pack into the Cylinders,

the more Horse-Power we make. The more Horse-Power we make, the more internal stress. The high strength studs are there

to insure the heads maintain a tight seal against the surface of the block. I'm not sure what the real figure is

in regards to added stress, but with the added pressure and more fuel, I would say it's at least doubled.

Now that we have the engine buttoned up once again, I got a chance to snap a few pictures and think about how we want the

Turbo-Chargers to sit. The best I could come up with is what you see here. The two (2) sides are not going to

be the same, they can not be, they are mirror images of each other. What I was able to do, is come up with a scenario

where we can get the two (2) sides as close as possible, a situation that will work. The Turbo-Chargers are clock-able,

meaning they have the ability to rotate on an axis. By loosening the six (6) 3/8" bolts on each compressor (Cold

Side) we can rotate the outlet of each compressor so they match. In this case they will both be pointing up. We

will attach a 90° bend right away, so we can redirect the flow of air to wards the Inter-Cooler. We have made sure

our oil inlet and it's corresponding Outlet are positioned straight up and down, prospectively. This is very important

for good oil flow. Next time I work on Project:Flathead, I'll

mount the oil inlet's and plumb the lines to and from the Turbo-Chargers. We'll use a AN-4 for the feed and

a AN-10 for the return or drain.

I did happen to mount the air filters, I wanted to make sure

there were no issues. For now I'll just leave them on as they protect the Turbo's from dirt and damage.

These last two (2) shots show the engine complete

with it's new Air Filters. I really like the look of them, they give the engine a jet-like look. Plus they

are compact and light weight. With the head studs out of the way, I suppose we will have to turn our attention to the

intake system, and the fuel management portion of the project. Also, it won't be too long till we design the frame

work that will hold everything in place

10-12-07

I haven't been doing to much latley,

but I did manage to get down to the shop today. I mainly did a bunch of stowing supplies, but after that I worked

a little on Project:Flathead. First thing I did, was to make a list of what was now needed. I thought I had some

An-10 Hose, but that was wrong, so on the list it went. The An-10 hose will be used for the Turbo-Charger's oil

drain back into the oil pan. Remember those two oil pan fittings we installed?? That is what they were for.

I also checked to see if we had the supplies to fashion the two oil feed lined to the Turbo-Chargers, and we had everything

but the oil inlet fittings. I was assuming we could simply screw in a 1/8" NPT fitting that converted to An-4,

but that was wrong also. The thread in the turbo body is some sort of Metric thread, so I ordered two oil inlet fittings.

Yes I know, But it is much easier and cheaper to just order the two oil inlet kits then try and find that adapter for the

fitting. If you look, you will not find any metric to AN fittings. So, with those two items out of the way, I

spent a little time visuallizing how the rest of the engine and it's intake system will look. Next time I get the

time, I'm going to start working on that, and se if we can't get something going. eally the rest of the project

depends on that key area.